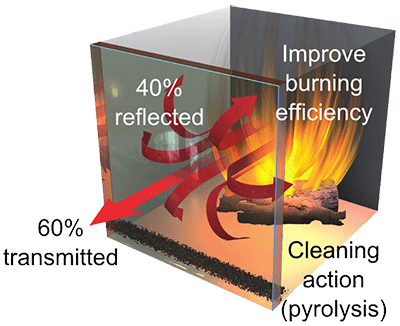

The ceramic glass ROBAX® exceeds the standard for thermal resistance. With an expansion factor of almost zero to 800 ° C it can resist almost all thermal shocks. That makes this glass ideal for fireplaces and stoves.

Ceramic glass is obtained after the specific heat treatment of a special glass paste called " glass precursor" which is brought into a low concentration of nucleating agent. The agents must be distributed as evenly as possible so that the crystallization proceeds optimally. The result is partially crystallized and partly micro glass material. The type and the configuration of the crystals are largely dependent on the composition of the precursor glass paste . Thanks to a more recent method there is no longer made use of a glass paste which but allows to crystalize the glass powder immediately from the beginning of the process.

Available in: Full crate / separate sheets / cut to size sheets

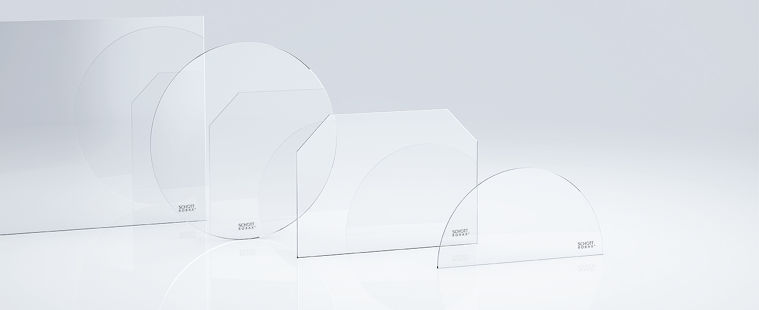

Ceramic glass ROBAX® 4mm : 890x1580mm, 1100x1954mm

Available in: rectangular or shaped / polished / sand blasted /screenprint / anti reflection / black / mirror

3 sides with 45° corners with polished edges.