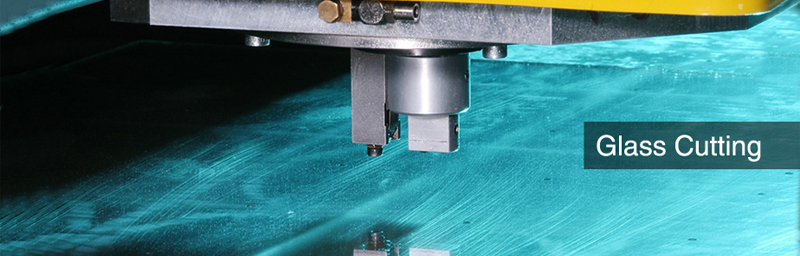

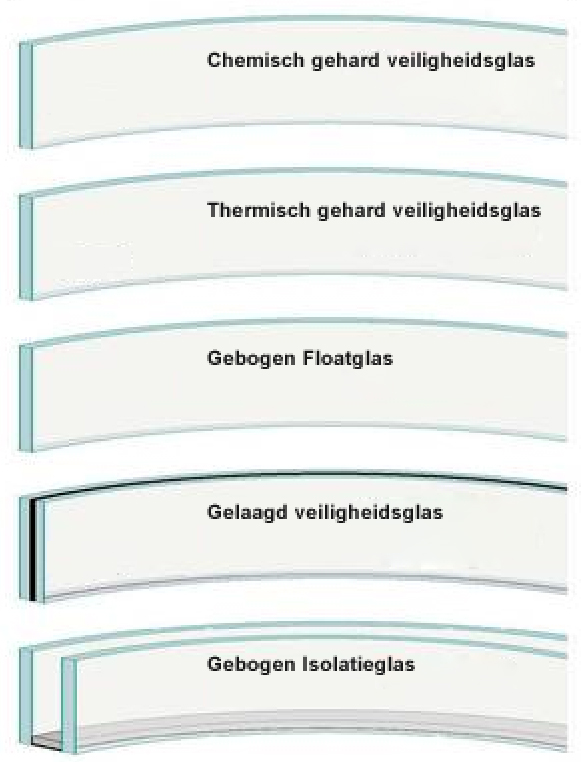

Alongside you can see a CNC cutting line, which is controlled by means of AutoCAD files (.dxf files). Therefore, your glass product can be processed close to 1 to 1, so that tolerances are minimized.

Glass polishing makes it possible to make the sharp side of the glass smooth and / or shiny, and also reduce the accuracy to +/- 0.5mm.

When polishing glass, there are multiple possibilities for different results. The following is a list of these possibilities.

The major part of the cutting is partially, or totally, carried out automatically. On our Intermac cutting table we can cut small amounts automatically.

Besides the regular polishing, we can polish the glass to make it convex or concave. With this cutting method, the glass gains a round edge (convex) or a hollow edge (concave). This operation is commonly used in hard glass walls in which different glass panes must be directly connected to one another. Because of the hollow and round side, they slide “into each other”, making it unnecessary to seal them. This creates an extremely stable wall with barely visible joints.

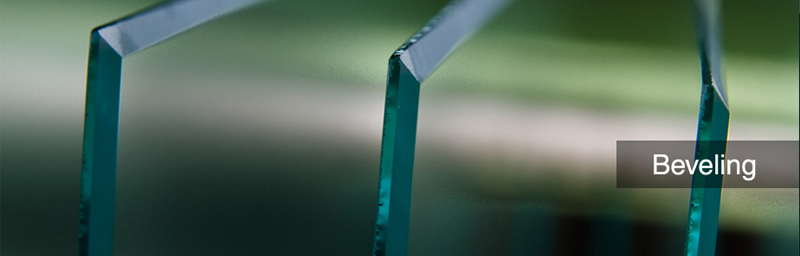

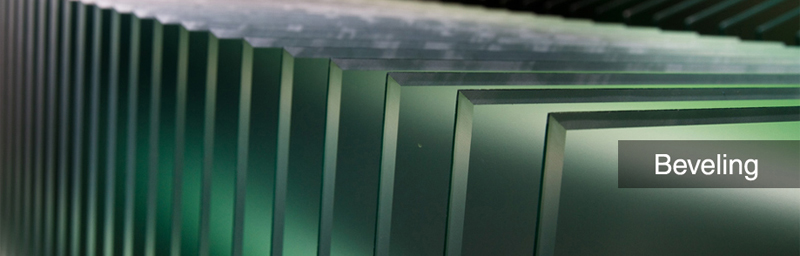

A facet is a sloping edge with a given width at

the edge of the glass. Virtually all types of glass,

in almost all amounts of thickness, can be fitted

with a sharpened facet edge. Because it is cut

under a certain number of degrees, the glass edge

becomes thinner as the facet widens. The thicker

the glass, the wider the facet can be made. A facet

can be made on both a straight glass plate, and

one having a different shape.

Depending on the thickness, facet widths are

available from 05 mm to 45 mm.

Miter cutting is the same kind of application as polishing. However, when polishing a facet, the discs press against the glass under a (variable) angle from 0 to 67.5 degrees. The thick side of the glass is ground and / or polished. It is possible that a residual value is retained.

This polishing operation is also a side process, which is used particularly in models. There must be enough space for the use of suction cups. The amount of tolerance starts, depending on the thickness, at +/- 1mm.

With our advanced CNC- machines, we can mill all kinds of shapes and notches in a glass bedding.

Alongside you can see a CNC cutting line, which is controlled by means of AutoCAD files (.dxf files). Therefore, your glass product can be processed close to 1 to 1, so that tolerances are minimized.

With this operation, we can make holes in glass. This is done from both sides, which means drilling from both the top as well as from the bottom. From the upper side, 50% is drilled, and up to 60% from the other bottom up, resulting in a nicely finished drill hole. By means of a conical finishing, a sloping side can be milled on the drill hole.

A decoration can be engraved into the glass. These engravings can practically have all forms; the width of the engraved slot is, however, up to 5 mm. It is possible to perform an engraving that is shiny.

By tempering the glass, also called tensioning, we are able to increase the structural strength by a factor of 4. It is then becomes safety glass, which disintegrates into small pieces when broken. This is realized under the DIN standard.

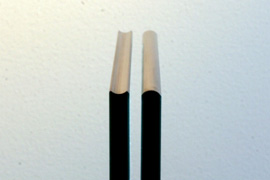

For years, New Glass Technolgoy has excelled in delivering various curved glass solutions. We are also able to bend the glass in difficult shapes. Whether the shape is spherical, conic or cylindrical, the only boundaries that limit the shape of the glass are determined by the laws of physics. New Glass Technolgoy bends glass for enterprises in various branches, such as yacht construction, the automotive branch, interior and decoration construction and architecture.

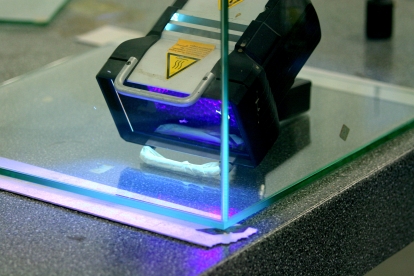

When using UV-gluing, a connection is made between glass / glass and glass / metal. The connection is made by means of photo bond glue that is highlighted in the range of the UV-A. The used frequency is about 380 Nm. The connections that are made are much stronger than the strength of the glass.

In modern architecture, screen-printed glass always creates surprising

effects. Glass in combination with color and light leads to a multitude of

creative possibilities for designing interior spaces and exterior facades.

With screen printed decorations, such as texts, repeated abstract forms and

colorful images, the creative possibilities are seemingly endless.

A screen-print is generally used for repeating work.

The glass is printed with ceramic paint by means of the screen-printing

technology. The paint is fired on the glass at +/- 600 °C, in which a superior

adhesion is made between the ceramic paint and the glass. This way of

working makes sure that the color cannot be removed from the glass, even

with a solvent. There are also no discolorations due to exposure to sunlight.

By burning in the paint at high temperature, the glass also gets the

mechanical and thermal properties of single safety glass. These colored

panels can also be further processed into laminated and / or insulating glass.

Most of the Ral colors can be used.

The application of digital printers is the latest development in the field of interior glass. The technology continues to improve so that larger glass surfaces can be printed, the prints become more sustainable, more resistant to UV, and also the brightness and the number of pixels increases with a positive effect on the quality of the image. A relatively new novelty on the market is digital printing on PVB film for use in laminated glass.