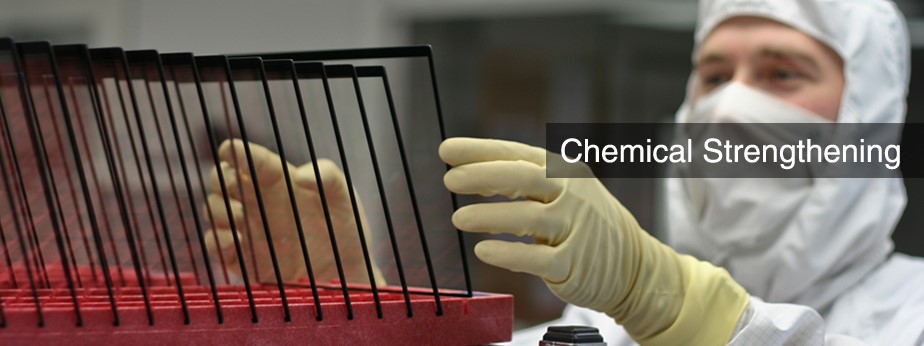

The purpose of chemically strengthened or toughened glass is the same as it is for thermal curing, but the treatment is a chemical process. The glass is immersed in a bath of molten salts at a temperature of approximately 400°C. The immersion time is crucial to obtain a certain voltage. The stress distribution of chemically strengthened or toughened glass is not the same as it is in thermally toughened glass.

The chemical hardness of toughened or chemically strengthened glass is mainly used for the solidification of thin glass with a thickness of 1, 2 or 3mm. For a chemical tempered treatment it is essential that the surface remains flat. This allows the manufacturers of copiers, solar panels, microwave equipment, meters, lighting companies in the technology, automotive engineering and many other users of flat glass to use tempered glass in their products en.

Because of its high strength toughened or chemically strengthened glass is not used very often in buildings and is especially designed for applications in the aviation and lighting industry.

Chemically strengthened or tempered glass provides the following benefits:

Further advantages for the use of thinner chemically toughened or strengthened glass with high hardness:

Almost all types of glass that have a high salt content can be solidified by an ion exchange.